Wire EDM

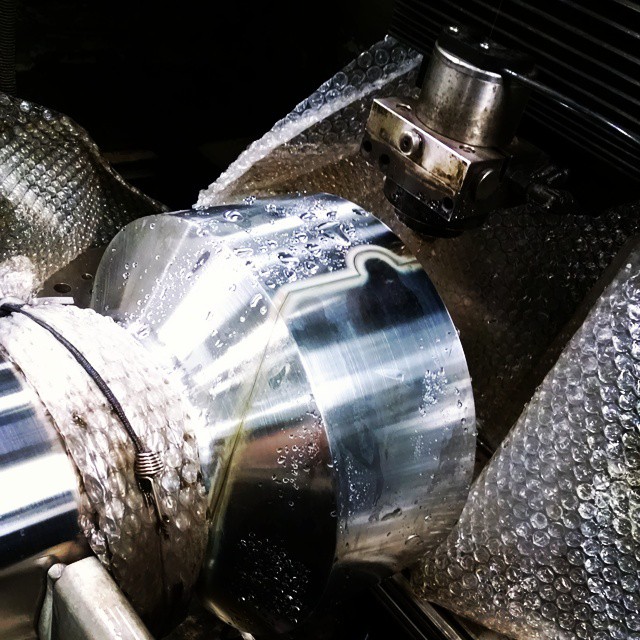

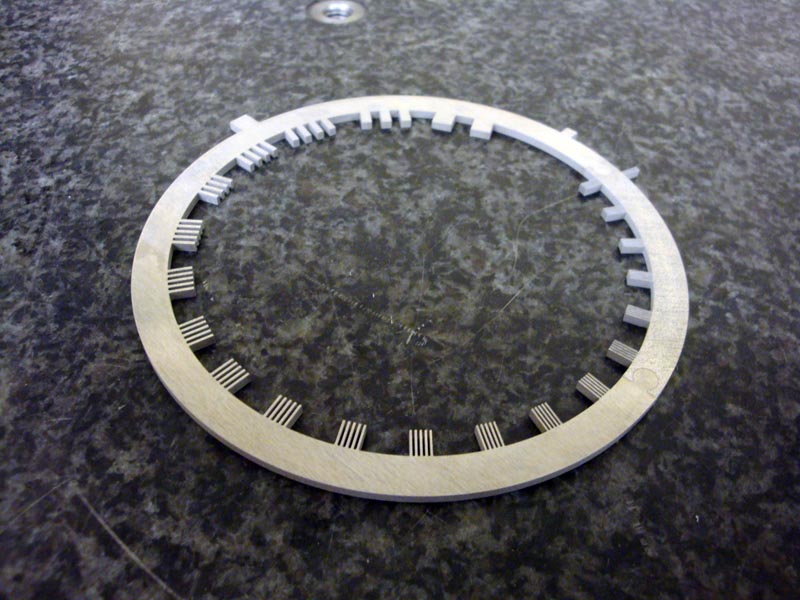

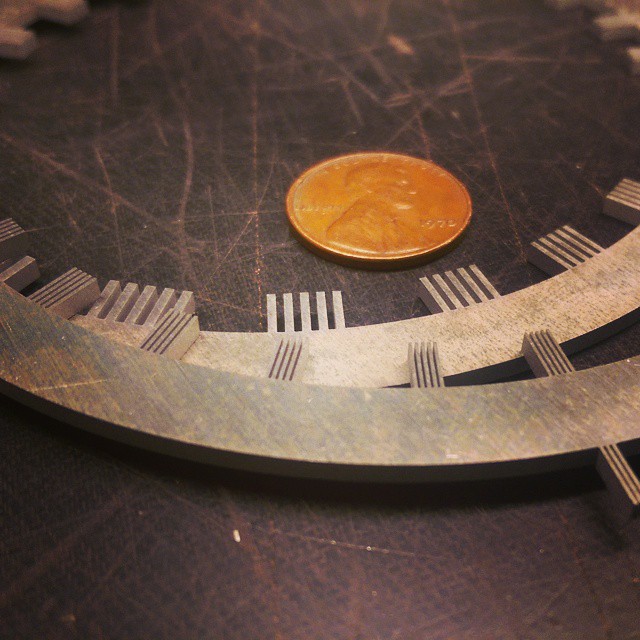

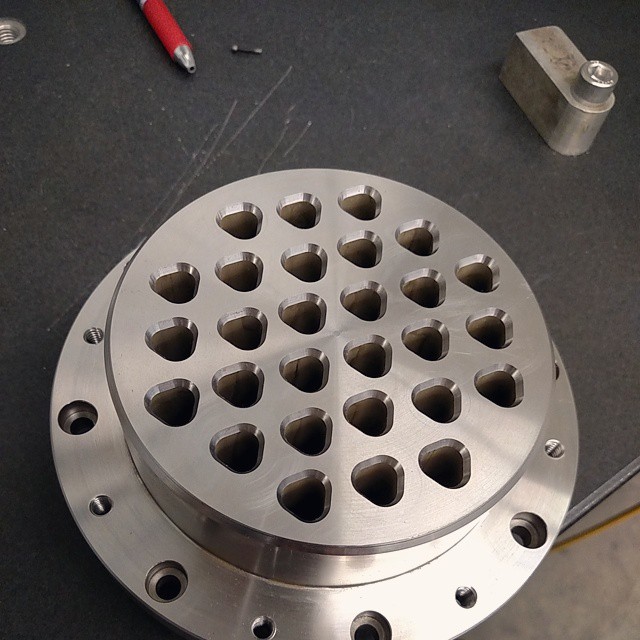

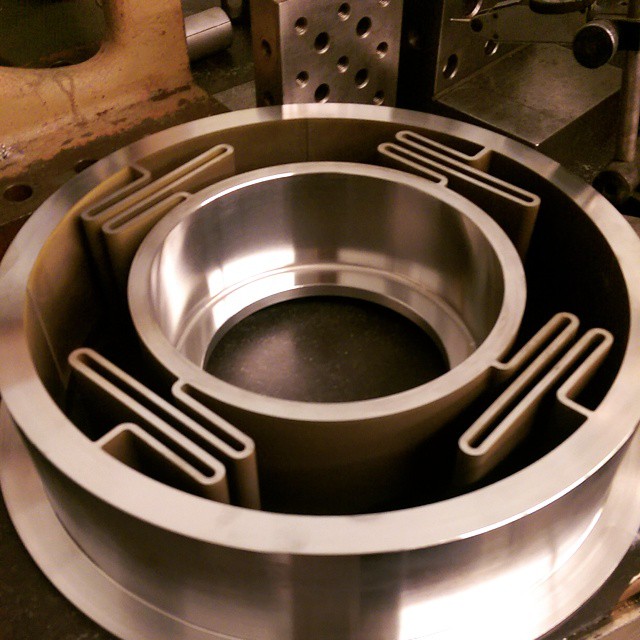

Electrical Discharge Machining (EDM) is a machining process by which electrically charged wire vaporizes material rather than cutting it by traditional methods. This allows for machining accuracies down to 2 microns (.00008”), radii as small as .001” ,and the ability to intricately cut difficult to machine high temp alloys such as Titanium, Carbide, Waspaloy, Hastelloy, Kovar, and Inconel.

AMT carved its niche in 1983 by being an early adopter of Wire EDM technology. We now have 5 Fanuc Robocut Wire EDMs, with our largest machine capable of cutting workpieces up to 22" x 15" x 16". We remain one of the largest Wire EDM job shops in the Northeastern United States.

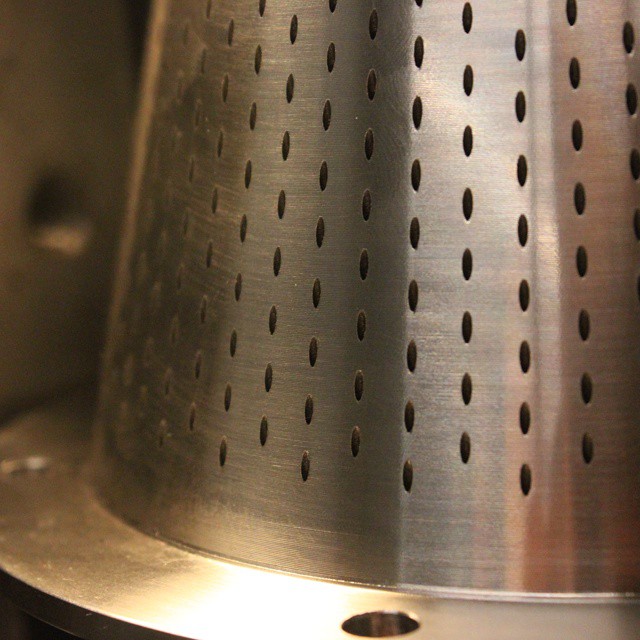

In 2012 we added a Yougar small hole EDM machine with a 4th axis, capable of drilling holes ranging from .012’’ to .118’’ up to 100 times diameter. The 4th axis makes this machine ideal for drilling small repeating holes around a circumference in difficult to machine alloys, often found in parts for the gas turbine and aviation industries.